Coloring aluminum with heat When heat treating a forged blade you get the whole knife glowing then submerge just the blade in the oil for 8 seconds. You can color any metal containing iron such as steel with the oven heat of an ordinary kitchen range.

Latest Coloring Aluminum With Heat

Coloring aluminum with heat. I have just come across this question and response. This process changes the temper of the extrusion and the color may be very different compared to a straight lineal. I m doing metal art using plasma torch mainly on 12 ga sheet steel.

While many commercially made dyes and paints are formulated for metal painting dyeing your project with ordinary food coloring allows the color to be transparent adjustable in tone and as easy to remove as the fixative you use to apply to. In fact the closer to black a color is the more heat it absorbs from light sources. Dark colors absorb a lot more heat than lighter ones because they absorb more light energy.

There are four ways to color aluminum. You can make a piece look newer with a coat of fresh paint create a vintage patina look or change the color by anodizing the metal. Other processes done to aluminum which cause color variation in anodizing are heat bending of extrusion and welding.

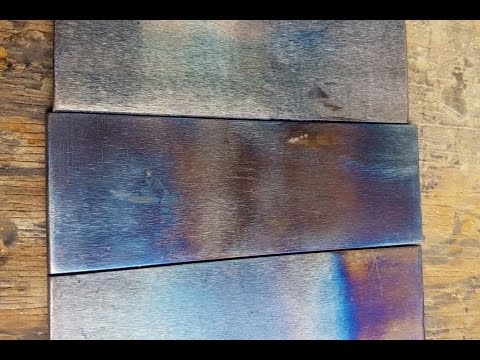

The key is that colors do not absorb different amounts of heat only heat from light. I ve looked everywhere i can think of on information on coloring the metal with heat and would appreciate any information on this technique. The metal just looks that color temporarily and will return to normal color on cooling.

The porous anodic coating absorbs the dye. Dark and light colored clothes coming out of a dryer will be the same temperature. Like other art mediums metal craft projects are often in need of elements of color.

Gray or unsightly aluminum may be restored to its white color by washing with a mixture of 30 parts of borax dissolved in 1 000 parts of water with a few drops of ammonia added. In addition literally hundreds of chemicals will change the color of metal surfaces. In a vacuum or inert atmosphere the metals do not change color until heated enough to glow from the heat.

The intensity of color is related to the thickness of the anodic film the dye concentration immersion time and temperature among other things. The freshly anodized part is immersed in a liquid solution that contains dissolved dye. The color is oxide but i believe you can scrape it off.

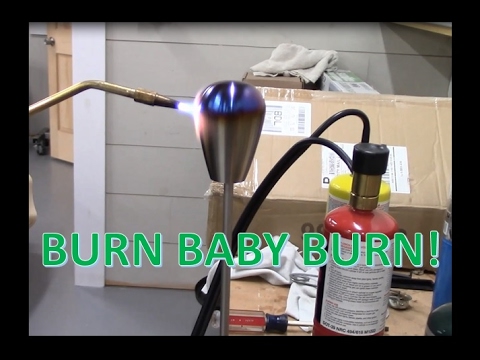

Next you hold it in front of your heat source until a blue oxide layer covers the whole blade edge. Depending on the temperature setting the steel changes color across a spectrum of shades ranging from pale yellow to dark blue. Heat bending is a crude process where an extrusion is heated using a torch and wrapped around a steel jig.

Mat aluminum in order to impart to aluminum the appearance of mat silver plunge the article into a hot bath composed of a 10 per cent solution of caustic soda. Then you pull it out and scrape off the oil along the blade edge. But that s just energy being released due to the heat.

Coloring metal can be done by several different methods depending on the type of metal and the look you are hoping to achieve.

Don't forget to bookmark using Ctrl + D (PC) or Command + D (macos). If you are using mobile phone, you could also use menu drawer from browser. Whether it's Windows, Mac, iOs or Android, you will be able to save the images Coloring aluminum with heat.